How it works

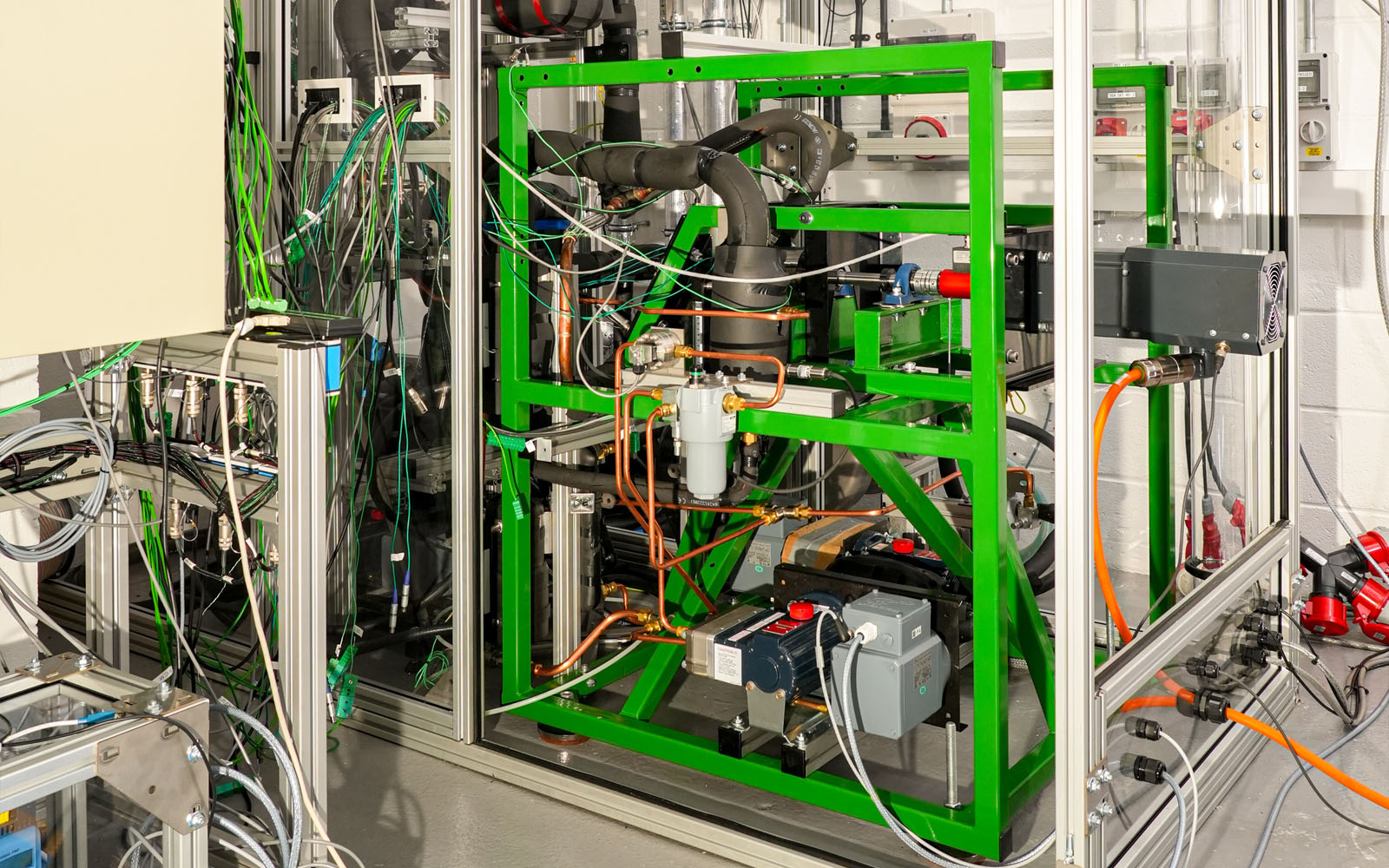

The low-loss, high efficiency, heat exchanger common to the FeTu system is placed within your gas or liquid process stream in order to cool the process flow whilst extracting heat into the FeTu based ORC media circuit.

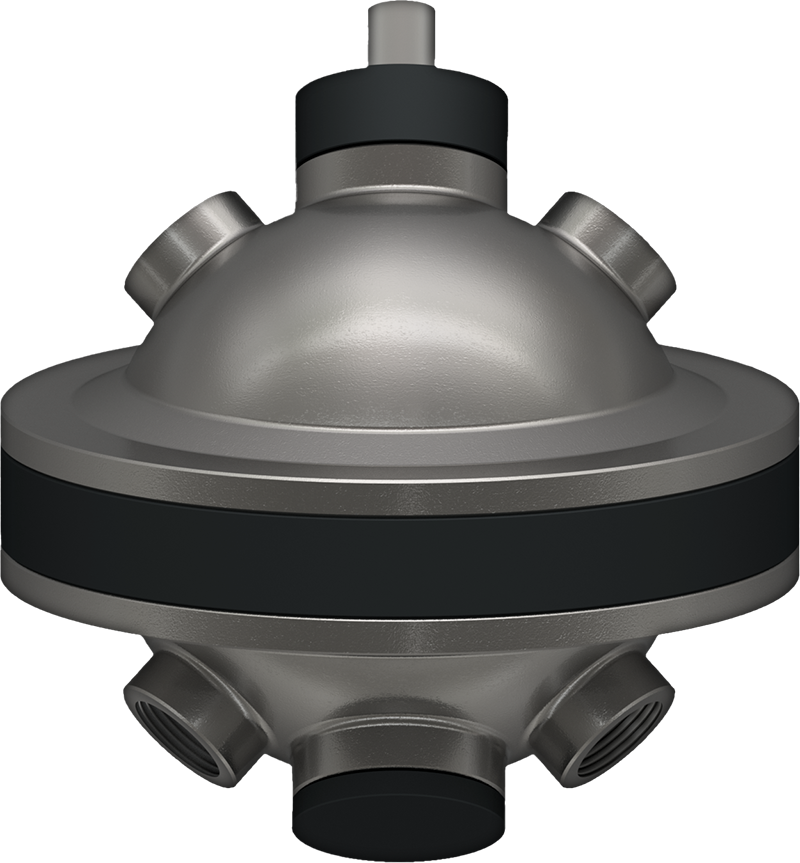

The fundamental differentiator of a FeTu based ORC system is the technology base of the expander architecture. A low GWP fluid is depressurised through a Fenton Turbine 'FeTu', this provides motive force which is used to drive a Motor Generator Unit (MGU).

More often an AC/DC/AC generation process is employed, providing frequency and voltage correction for localised use and load balancing. FeTu recommend energy use at point of generation, in order to offset grid demand and realise maximum value of generated power.

Low temperature heat must be rejected from the system. Usually by means of a second heat exchanger discharging into an atmospheric water or air source. Sink temperature and system performance are intrinsically linked, the cooler the better.